- JP

- EN

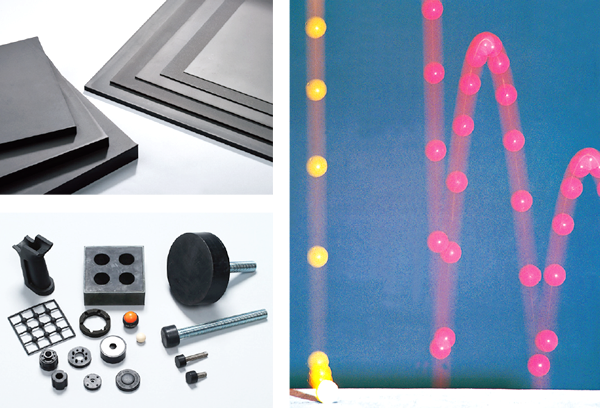

HANENITE vibration suppression rubber has excellent performances of absorbing shocks and vibrations. Even when external force is applied,the rubber absorbs the energy with almost no repulsion.The material has excellent physical properties and durability comparable to those of normal rubber.This is the rubber that does not bound when it falls,defying the common sense of rubber.NAIGAI presents this material to materialize quiet and low-vibration products.

| Form of application | Field of application | Function | Application example |

|---|---|---|---|

| Support material |

OA equipment Personal computer Precision instrument Mobile system Industrial machinery |

shock absorption |

Rubber feet of PC,hard disk support material,shock absorber of LCD,PCB support material,rubber feet measuring instrument,shock absorber of car navigation sysytem,rubber feet of industrial sewing machine,shock absorber of POS system,and shock absorber of mobile phone against dropping. |

| Vibration part support material |

AV equipment OA equipment Personal computer Industrial machinery |

Vibration suppression | |

| Cushioning material |

Industrial machinery Transportation machinery Musical instrument Leisure products Sporting-goods |

Cushioning | |

| Vibration suppression material |

Audio Mobile OA Precision equipment Construction and earthmoving equipment |

Vibration suppression |

| Product type | Unit | ||||||||

| GP-35L | GP-60L | CP-40S | CP-55S | GP-40HB | GP-50V | OP-40 | Sponge | ||

| Mechanical properties | |||||||||

| Hardness (typeA) |

32 | 55 | 42 | 56 | 42 | 51 | 39 | 25 (SRIS C) |

|

| Tensile strenght | Mpa | 10.3 | 8.3 | 9.5 | 7.7 | 8.5 | 5.6 | 12.5 | 0.9 |

| 〃 | kgf /cm2 |

105 | 85 | 97 | 79 | 87 | 57 | 128 | 9 |

| Elongation | % | 840 | 810 | 800 | 640 | 700 | 680 | 770 | 480 |

| Tear strengh | kN /m |

12.5 | 17.8 | 19.6 | 23.5 | 13.2 | 16.4 | 18.5 | 9.1 |

| 〃 | kgf /cm |

12.8 | 18.2 | 20 | 24 | 13.5 | 17 | 18.9 | 9.3 |

| Repilsion slasticity | % | 2 | 2 | 12 | 13 | 6 | 5 | 9 | 10 |

|

Compression permanent set |

% | 17 | 16 | 15 | 18 | 13 | 19 | 14 | 62 |

| Static shear elastic modulus | Mpa | 0.28 | 0.4 | 0.27 | 0.74 | 0.37 | 0.45 | 0.34 | 0.04 |

| 〃 | kgf /cm2 |

2.89 | 4.13 | 2.74 | 7.54 | 3.64 | 4.63 | 3.51 | 0.43 |

| Specific gravity | 1.24 | 1.3 | 1.14 | 1.2 | 1.35 | 1.49 | 1.18 | 0.3 | |

| Heat resistance Air-heated aging test conditions:70℃×96Hr | |||||||||

| Rate of change in strength | % | -7 | -2 | -6 | -1 | 15 | -1 | -1 | 7 |

|

Rate of change in elongstion |

% | -15 | -13 | 4 | -2 | -2 | -8 | -3 | 2 |

| change in hardness | % | 3 | 2 | 1 | 1 | 3 | 3 | 0 | 4 |

| Oilproof and waterproof Swelling test conditions:Weight change rate (%)after 40℃×24Hr | |||||||||

| JIS#1 Oil | -0.6 | -0.3 | 3.2 | 2.2 | 0.1 | 0 | 7.4 | 13.9 | |

| JIS#2 Oil | -0.2 | 0.2 | 16.3 | 16.3 | 0.3 | 0 | 7.9 | 11.6 | |

| Fuel C | 0 | 7.6 | 158 | 124 | -6.8 | 2.7 | 118.0 | 99.9 | |

| Fuel D | -5.1 | -3.7 | 163 | 127 | -1.8 | 1.2 | 121.0 | 72.5 | |

| Engine Oil SF | 1.4 | -0.4 | 12 | 7.8 | 0.2 | - | - | 9.5 | |

|

Engine Oil SH |

- | - | - | - | - | -0.5 | 22.9 | - | |

| Antifreeze | 1 | 0.9 | 0.2 | 0.2 | 0.2 | 0.2 | 0.5 | 10.1 | |

| Pure wate | 0.8 | 1.5 | 0.3 | 0.2 | 1.6 | 2.9 | 0.5 | 15.6 | |

| Cold-resistance Tg(℃) 100Hz | |||||||||

| Tg | ℃ | 15 | 20 | -15 | -20 | 11.6 | 10.2 | 12.6 | 17.7 |

| Ozone-resistance Ozon-resistance test conditions:50pphm×40℃×20%elongation | |||||||||

|

Exposure 6Hr |

N.C. | N.C. | N.C. | N.C. | - | - | - | N.C. | |

| Exposure 24Hr |

A-2 | A-2 | C-2 | C-2 | - | - | - | B-3 | |

| Exposure 48Hr |

B-3 | B-3 | C-4 | C-4 | - | - | - | B-3 | |

| Exposure 96Hr |

B-5 | B-5 | C-4 | C-4 | - | - | N.C. | B-4 | |

*Test methods compliand with the standards shown on the right.

*The measurement values are not guranteed performance values.

| Hardness | JIS K6253 |

Static shear elastic |

JIS K6254 |

| Tensile | JIS K6251 | Air-head again test | JIS K6257 |

| Tear test | JIS K6252 | sweliiing | JIS K6258 |

| Repulsion dis | JIS K6255 | Tg | JIS K7244-4 |

| Compression permanent | JIS K6262 | Ozon-resistance test | JIS K6259 |